With the automotive market experiencing change at an unprecedented rate, Flex offers the solutions and services that matter most. Like flexible business models to suit the needs of our customers, advanced product design capabilities, broad cross-industry expertise, and world-class manufacturing and supply chain capabilities.

At Flex, we have decades of automotive design and manufacturing experience and know that resiliency and adaptability are key. That’s why we offer a broad range of automotive capabilities, from traditional agile manufacturing services for individual automotive projects, to joint and full-product development for tailored next-generation mobility solutions.

We also know the importance of collaboration, so we work with the entire mobility ecosystem, including OEMs, technology providers, and key diverse suppliers. Our award-winning product design and manufacturing solutions are used by companies around the world looking to accelerate innovation to market, optimize production, improve product quality, lower operating costs, and increase overall business agility.

We deliver expertise on the power electronics fueling electric vehicles, to the computing platforms supporting the software-defined vehicle and the motion and interfaces that form a vital in-vehicle infrastructure.

With over 30 automotive sites, including five dedicated automotive design centers, in over 15 countries, Flex has the global manufacturing size and scale to partner with any company, anywhere.

As an established automotive supplier to OEMs and Tier 1 suppliers around the world, we’ve been recognized for our designs, innovations, quality, and supply chain commitment by both our customers and industry publications.

As the world around us becomes smarter and more connected, the automotive industry is experiencing a massive transformational shift, one that is powered by rapid technological advancements and enabled by new business models in how OEMs and suppliers work together. As next-generation mobility continues to evolve rapidly, we offer the agility, efficiency, and speed of advanced manufacturing, tightly coupled with a broad range of design capabilities and deep supply chain partners for innovation acceleration and faster time-to-market.

Our services and offerings are aligned with the latest trends driving next-generation mobility and support the rise of software-defined vehicles which require faster development cycles and flexible business models. As a multi-industry global company, Flex brings together technology and best-practice expertise spanning our diverse business segments. From electric vehicle charging stations and other power infrastructure, to cloud and edge computing and other data infrastructure, we uniquely support the entire mobility ecosystem. Our automotive product design capabilities and development platforms enable the technologies essential to powering the future of mobility.

Our award-winning solutions are designed to accelerate the transition from internal combustion engines to zero-emission electric vehicle platforms. Flex offers exceptional cross-industry expertise in power electronics systems.

Software-defined vehicles demand robust and reliable hardware to enable a future of safe and smart mobility. We provide the scalable compute and new vehicle architecture solutions needed to make this future a reality.

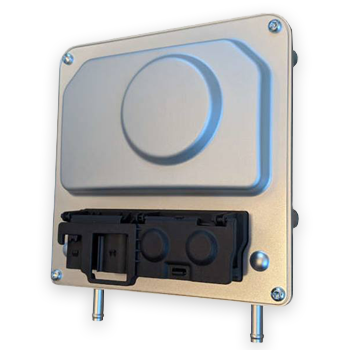

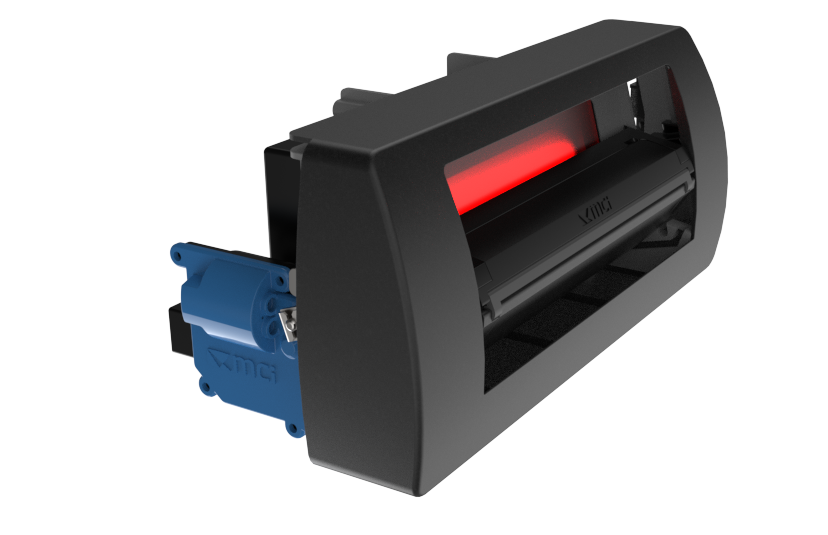

Every piece of technology has inputs, outputs and connections; the cars of today and tomorrow are no different. With decades of experience, we provide solutions that allow the power and data architectures to connect and interact with users, the rest of the vehicle, and the world around it.

With over 30 automotive sites located in over 15 countries (including five dedicated automotive design centers), Flex has the global manufacturing size and scale to partner with any company, anywhere. Our network of more than 4,000 automotive suppliers allows us to help navigate supply chain challenges, manage forecasting, and recommend in-region strategies. Working with Flex enables automotive companies to improve resiliency, mitigate supply gaps, minimize risk, and quickly scale production. We have products on over 600 unique vehicle platforms globally and more than 100 automotive customers with well over half of our business direct to OEMs.

Certified sites for ISO 26262, ASIL-D, ASPICE, TISAX, and more provide the highest possible quality of automotive-grade products and services.

Continuous investments into design and innovation offer turn-key product solutions and development platforms to accelerate time-to-market.

Agile manufacturing and our global presence provide the supply chain flexibility to source components and build products in region or rapidly shift production to other worldwide locations as demand or regulations change.

Highly skilled customer support teams work to ensure every partner, customer, and supplier receives exceptional customer service and high-quality products.

Design-for-manufacturing services provide expertise that enables products to be designed for the best possible manufacturing yield, quality, and cost.

Advanced manufacturing technologies and processes utilized in our factories around the world boost productivity and efficiency while lowering downtime and costs.

Real-time data analytics are leveraged to manage complex supply chains and help drive best practices and continuous improvements.

Flex’s collaborative engagement models and design expertise allow us to address the unique and complex needs of the mobility industry, while our global manufacturing scale and broad supply chain network enable us to quickly adapt to global macroeconomic challenges and the rapidly changing dynamics of the mobility markets to help our customers remain at the forefront of innovation.